FlowMark Disinfection Systems “How it works”

Introduction

FlowMark Disinfection Systems (DS) have been developed to enhance biological control of our Web Induction Pulse Power Water Treatment product line. Dozens of cooling towers are maintaining excellent biological control using only our Web Induction Pulsed Power System as it promotes calcification of microbes which limit their ability to metabolize nutrients and dispose of waste. Typical Bacteria Plate Counts (HPC) average 500 CFU/ml or less with our Mark series products alone. In cases where the mineral content of the make-up water is too low to promote calcification of microbes or when persistent algae growth is a problem we now have the product to fill the gap with FlowMark DS Systems.

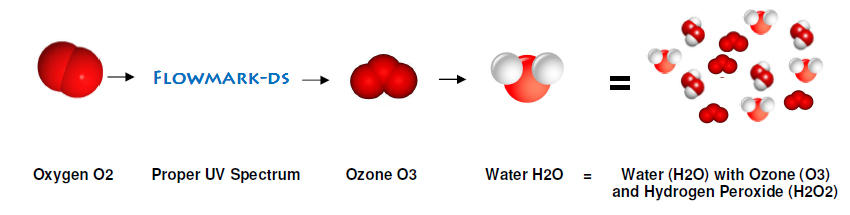

How FlowMark DS Systems Work

FlowMark DS Systems work by generating a powerful disinfecting gas and introducing it into the cooling tower water through submerged diffusers installed in the cooling tower basin. The process is recognized by the EPA as “Advanced Oxidation Process”. Ambient air is pumped through a chamber that contains a special UV Lamp generating a wavelength that splits oxygen into singlet oxygen molecules. Since oxygen does not naturally maintain a singlet molecule form it rapidly reforms in groups of 3 which is ozone, a powerful, natural oxidizer which is stronger than chlorine.

Shortly after introducing the tiny oxidizing bubbles to the cooling water a measureable level of Ozone is detectable. As an added benefit, Hydrogen Peroxide ( a proven disinfectant) is created and maintains a long lasting measureable residual in the water.

Wikipedia Definition of Advanced Oxidation Process (AOP)

Advanced oxidation processes (abbreviation: AOPs), in a broad sense, refers to a set of chemical treatment procedures designed to remove organic (and sometimes inorganic) materials in water and by oxidation through reactions with hydroxyl radicals (·OH). In real-world applications of water treatment, however, this term usually refers more specifically to a subset of such chemical processes that employ ozone (O3), hydrogen peroxide (H2O2) and/or UV light.

AOPs rely on in-situ production of highly reactive hydroxyl radicals (·OH). These reactive species are the strongest oxidants that can be applied in water and can virtually oxidize any compound present in the water matrix, often at a diffusion controlled reaction speed. Consequently, ·OH reacts unselectively once formed and contaminants will be quickly and efficiently fragmented and converted into small inorganic molecules.